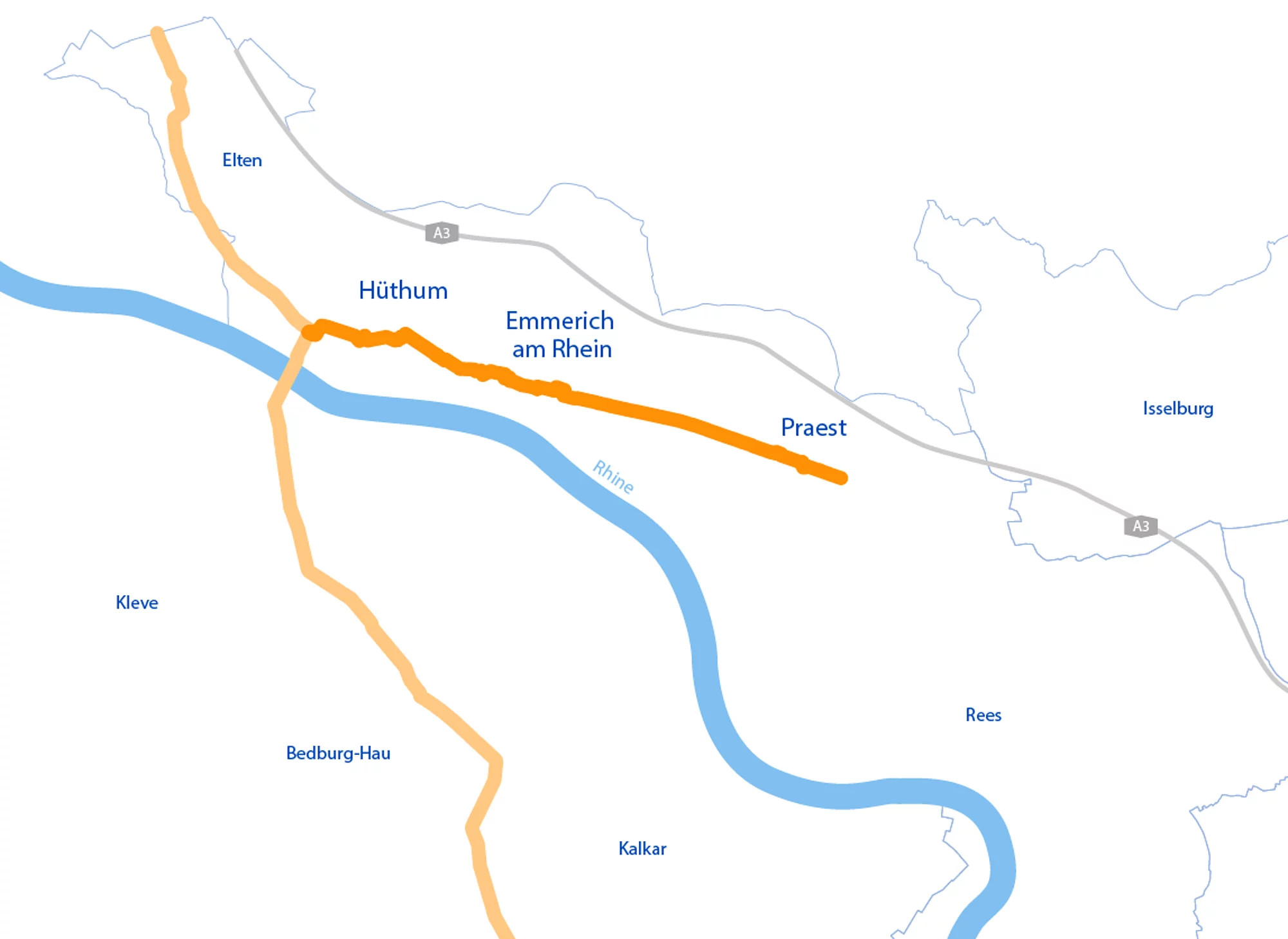

On the Lower Rhine in the Kleve district, we are providing a hydrogen supply perspective for industry and SMEs. To this end, we are converting around 14 kilometres of a natural gas pipeline in Emmerich am Rhein between Hüthum and Praest to transport hydrogen. The interaction with our emerging Elten-St. Hubert H2 pipeline, one of the import corridors for hydrogen from the Netherlands, will give the region's economy a real locational advantage from 2030.

What do the H2 projects mean for the municipalities and companies along the pipeline?

With our H2 pipeline network, we are connecting the region to the future hydrogen motorways in Germany. Municipalities, industry and SMEs thus gain an H2 supply perspective and the opportunity to organise energy-intensive processes sustainably with the help of hydrogen.

Interested municipalities and companies can use our contact form to report their requirements for hydrogen feed-in or feed-out at any time. We will then check the possibility of a connection to our H2 infrastructure.

Municipalities also play a central role in our project beyond the H2 supply. After all, they are important partners for the successful realisation of the project. This is why we seek dialogue shortly after the start of the project in order to develop the best solution together with local stakeholders and those affected.

How is an existing pipeline converted to transport hydrogen?

For a conversion, the strict regulations of the Energy Industry Act and the Ordinance on High-Pressure Gas Pipelines must be complied with. The same high safety standards apply to H2 pipelines as to natural gas pipelines. Each pipeline is checked in advance by an independent expert to ensure that it is suitable for hydrogen. Specific measures that must be carried out before the changeover are recorded (e.g. technical adjustments, measurement of the pressure curve, adjustment of maintenance intervals for leak checks). Before the pipeline is commissioned, it is then approved by an independent expert. Our colleagues from the network control centres then take over and ensure safe operation through regular inspections and maintenance.

Why is Thyssengas converting existing gas pipelines for hydrogen transport?

Hydrogen is gaseous and can be stored in the same way as natural gas and transported to consumers in gas pipelines. Thyssengas already has an extensive network with around 4,400 kilometres of pipeline. Converting existing pipelines for H2 transport is sustainable and involves less interference with nature and the environment. Of course, conversion is also faster, as pipeline routes no longer need to be developed and authorised.

How do those affected find out about a planned H2 pipeline?

For us, proactive information and dialogue are an integral part of all pipeline construction projects. From the early planning phase onwards, we inform all those affected about the current status of the project at regular intervals - for example via press releases and on our website. Our on-site dialogue and information events also offer the opportunity to enter into a direct exchange with us and ask questions about the project.

Is the operation of a hydrogen pipeline dangerous and how does Thyssengas ensure the safe operation of the planned H2 pipeline?

No, the transport of hydrogen via pipelines is a proven and safe technology. The same high safety standards apply to H2 pipelines as to natural gas pipelines. Thyssengas has over 100 years of experience in gas transport and is continuously developing proven control and maintenance processes. Safety is always our top priority - this applies to the construction, operation and maintenance of our pipelines.

Whether natural gas or hydrogen. Our pipelines are monitored 365 days a year. The experts in the network control centres are on duty around the clock, checking the pipelines, organising maintenance and coordinating construction measures in the catchment area of our pipeline network. Regular inspections and aerial surveys of the routes ensure additional safety.

How much land does an H2 pipeline take up and what does this mean for agricultural use?

For the construction of the pipeline, a construction strip up to 40 metres wide will be created along the route. The measures required for this, such as earthworks and tree felling, are part of the approval process in advance. Once the work has been completed, the construction strip will be recultivated. A protective strip between two and six metres wide will remain to the right and left of the pipeline, but this can be used for agricultural purposes without any restrictions.

During the construction work, the areas affected by the construction work cannot be used for agricultural purposes. Any damage incurred (e.g. crop failure) will of course be reimbursed. After recultivation, normal agricultural use can be resumed immediately. The permissible cultivation depth of the field / field in the protective strip to the right and left of the pipeline is generally up to 60 centimetres.

Together into the energy future

In our projects, we work together with local stakeholders to find the best solution! We focus on dialogue, transparent information, personal discussions and local events. You can contact the project team at any time by e-mail: